Wooden Pallets: Stringer vs Block

There are many kinds of wooden pallets you can find on the market. Stringer pallets and block pallets are just some of the wooden pallet examples. Believe it or not, both pallets have their own special uses and their own differences. Ultimately, their final usage goal is to help make trans-oceanic transportation of goods a lot more convenient.

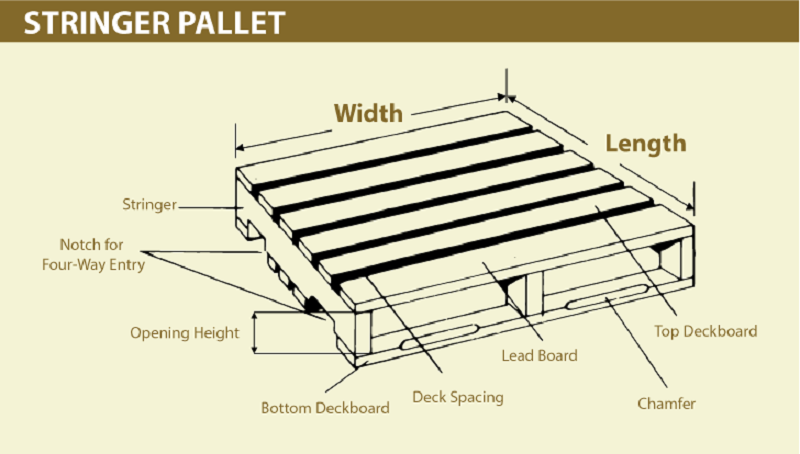

Stringer Pallets: What Are They?

A stringer pallet is called as such because it uses stringers to support the unit load. The stringers are the boards, usually 2 x 4’s or 3 x 4’s. They are packed in between the top and bottom deck boards.

When specifying the stringer pallet’s size, the length is usually noted first. Then follows the width, or its length will be noted second. A lot of times, stringer pallets may come in notches to allow for 4-way for entry. Hence, creating 4-way stringer pallet.

If you do not notch the stringers, then it is a 2-way pallet instead. They usually come with fork entry only from either end. You can chamfer bottom deck boards to allow entry for the wheels of a pallet jack.

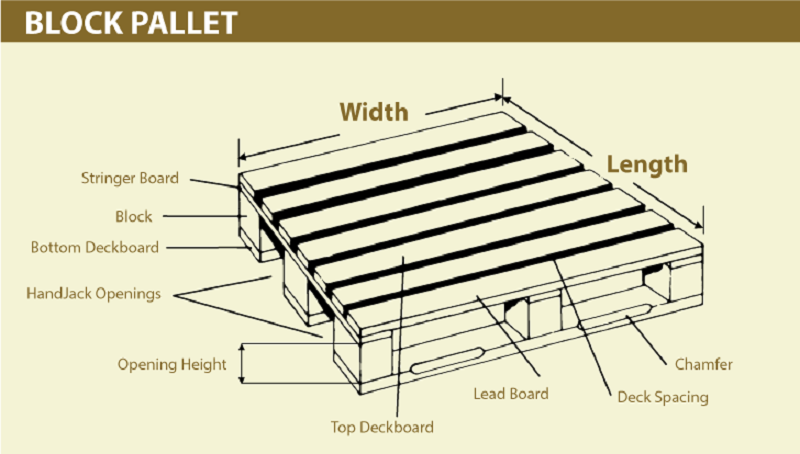

Block Pallets: What Are They?

Block pallets are legitimate and true 4-way entry pallets. They use blocks of solid wood, plywood, or plastic to support your unit loads. Usually, block pallets use 4 to 12 blocks to support the top part of the deck boards.

Similar to the stringer pallets, the length of a block pallet is specifiable by the length of the stringer board. Its width is specifiable by the length of the deck boards. Just so you know – you can design block pallets with or without bottom deck boards or a full-on perimeter base.

Both stringer pallets and block pallets can have a variety of deck board configurations:

- Number

- Width

- Spacing

On top of that, you can use plywood or orientation strand boards (OSB) as a deck material. They are also known as panel deck pallets. In special cases, some kinds of synthetic foam can replace stringer pallets or blocks. People often call them floater pallets and are for cushioning unit loads.

Stringer Pallet vs Block Pallet: A Comparison

| Stringer Pallet | Block Pallet |

| They come in sizes of 2 x 4’s or 3 x 4’s. It’s packed in between the top and bottom deck boards. | There are usually 9 blocks in a block pallet, with a solid wood block positioned in each of the 4 corners, in the middle of each side of the pallet, and in the middle of the pallet itself to support the entire unit load. |

| Stringer pallets come across looking as weak and easily breakable. They are not as they can withstand up to 1200psi worth of pressure. | Block pallets are stereotypically assumed to be stronger and more durable than stringer pallets mostly due to how they utilize both parallel stringers and perpendicular blocks. However, you can see that it’s not necessarily true. |

| Stringer pallets are able to withstand being dropped from a fairly high height with very little to no damages. This is done on an experiment of heights of 12mm (minimum) to 42mm (maximum). | Block pallets can’t really withstand falling from tall heights. Upon hitting the ground from being dropped at a tall height, it splits. Its gaps split anywhere from 10mm to 18mm when dropped. |

The above table is a quick comparison between stringer pallet and block pallets. Both have their own uses.

More Comparison Between the 2 Wooden Pallets

| Stringer Pallet | Block Pallet |

| A stringer pallet allows a full coverage base for your shipping and marine transportation needs. | Block pallet has three different base options for your shipping and marine transportation needs. It can have perimeter based, uni-directional based, or have an overlapping base. |

| Stringer pallets are stereotypically made of wood and wood materials. | Block pallets can be made from wood materials or plastic materials. |

| The original model of a stringer pallet is a lot different from a traditional block pallet. A stringer pallet is only available to be picked up from a 2-way entry – unless specifically notched to have a fractional 4-way entry. | A block pallet is nearly always accessible from a 4-way entry. This is because block pallets have hand jack entryways. Along with the openings, a block pallet has approximately 4-12 blocks supporting a unit load. A lot of times, these are located between the top of the pallet and the bottom deck boards. |

Block Pallet Uses

Even though the table makes it seems like stringer pallets are the best, it does not mean that the block pallets are any worst for use. There are some good uses that you can use block pallets for.

- Heavy goods shipper. Heavy mass items like bottle water, beverages, and can goods are heavy for very good reasons. A block pallet is the better option than a stringer pallet for these goods. That is because it’s the more robust construction of the block pallet that can handle the weight and movement easier than a stringer pallet and with less risk of any failure.

- Multi-step chain. A block pallet is more than likely to hold itself together through repeated handling than a stringer pallet. Because of this reason, it makes block pallets a better choice for complicated supply chains that oversees loads of product changing hands several times.

- Reducing wasted materials. Block pallets are usually able to make many more journeys through the supply chain than your usual stringer pallet. If a logistics manager is in the situation to set up a reverse supply chain to bring them back to the production site. This is as soon as they’ve completed a trip through the supply chain. After that, then these block pallets can reduce the need to constantly restock a supply of pallets.

Conclusion

Supply chains can enjoy these wooden pallet advantages with very little supplementary effort through the use of a wooden pallet pooling system. These wooden pallets manage the transportation and supply of pallets. This is to ensure they are already available when and where people want them. Choosing a pallet isn’t entirely about block pallets against stringer pallets anymore. By the end of the day, sturdy wooden pallets offer an alternative that’s superior to any other pallets.

Contact Us